Product Applications

- Freeze Dried Coffee

- Hair Spray

- Insecticides

- Self Defense

- Spray Paints

- Lubricants

- Deodorants

- Household Products

- Electrical Products

- Veterinary Products

- Electronic Cleaners

- Pharmaceutical

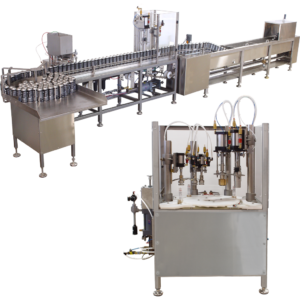

Production Rates

Maximum production rates up to 60 Fills Per Minute

Product Benefits

Faster Indexing: The rotary indexing starwheel design provides reduced transfer distance and accurately controlled container “stop” positioning for faster indexing.

Increased Production Rates: A unique component actuation cam and interlocking circuit eliminate all non-productive time to substantially increase machine production rate.

Positive and Accurate Container Control: A quiet, smooth, fast and efficient single or double-indexing drive mechanism provides accurate container positioning at each of the precision packaging components.

Space Efficient: Smaller machine bases and efficient conveyor layouts substantially reduce the amount of floor space required.

Labor Efficient: Labor requirements are reduced as the machine layout allows the container feeder operator to inspect for container leaks at the test bath. In addition, all of the machine components are readily accessible to the valve placing operator for QC inspection and machine adjustment.