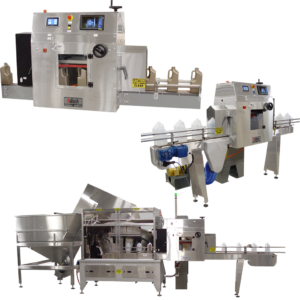

Nalbach Engineering’s Inline “360” degree orienter quickly, simply and inexpensively orients bottles into a common direction.

The NECO-ORIENTER “360” is a dual servo driven system.

Bottles are accepted from a single lane source and, based upon a Vision system’s output, allowed to pass if they are properly oriented or spun as required by the servo driven system if they are not properly oriented.

The vision system “looks” at the bottles as they enter the camera section of the enclosure and determines the actual angle of the bottles relative to the desired angle. The bottles actual angle is sent to the dual servo system to spin the bottles the required number of degrees to achieve the desired angle of the bottle at discharge for the system.

The NECO-ORIENTER 360 is available as a stand-alone product to meet the needs of many existing production lines or as a fully integrated option with Nalbach’s line of plastic bottle unscramblers.

As an option for plastic bottle unscramblers, the NECO-ORIENTER 360 and the unscrambler share a common HMI, vacuum conveyor and footprint, providing a complete and compact, fully integrated, solution for empty bottle handling.

Product Benefits

- It is fast with speeds to 300 bpm.

- It is simple with direct coupled servo motors and belts being the only moving parts in the system.

- The system’s simplicity means lower cost, lower maintenance and higher reliability.

- The system’s direct coupled servo driven design reduces part count while providing speed and accuracy.

- The system’s vision system can detect the smallest details for fast, easy, and accurate system setup.

- The system is small and compact for easy integration into existing layouts without requiring a large section of dedicated conveyor.

- Simple, repeatable adjustments for height and width allow quick and accurate changeover from one bottle format to another.

Video - English

Video - Español

View in 3D

Left Click to Rotate / Right Click to Drag / Scroll to Zoom.

Click the “Select an annotation” button to review features.

Click the “Fullscreen” icon in the lower right corner to maximize.